This design is slowly going out of style after all these years, but I like this kind of band saw the best. I also have one I’ve had since I was five or six years old my dad got it and now it’s mine. One I purchased in a whole-shop buyout in 1990, and I paid about $100 for it. The controls are all the same, and have always been the same throughout that time period. They have the same cast-iron arm-they’re sturdy machines. The Delta has the same design from the ’30s through the ’90s. I like the classic 14” Delta because it has easily adjustable guides-a lot of band saws require keys to adjust the lower guides, but the Delta has knobs so you can do it by hand. It’s definitely a great tool to have if you’re just getting started. You can cut straights if you put a deep blade on it, you can cut curves, and you can cut metal, wood, plastic, and leather.

If you’re going to get the first tool for your workshop, I always tell people to get a band saw. A lot of time I use it with wood, but if I slow it down with pulley reduction, I can cut metal with it. I just put a tarp on it when I’m not cutting on it. I leave it outside because it doesn’t fit in my shop, and mice make nests inside of it. I also have a Kalamazoo chopping band saw I rescued from the New York City seaport where it was about to get scrapped for metal. It features a 72” long by 3/4” wide blade with 6 TPI (tooth per inch), which is pretty aggressive for a metal-cutting band saw. It’s not the highest quality, but it works great for me, and the same blade has been on it six years.

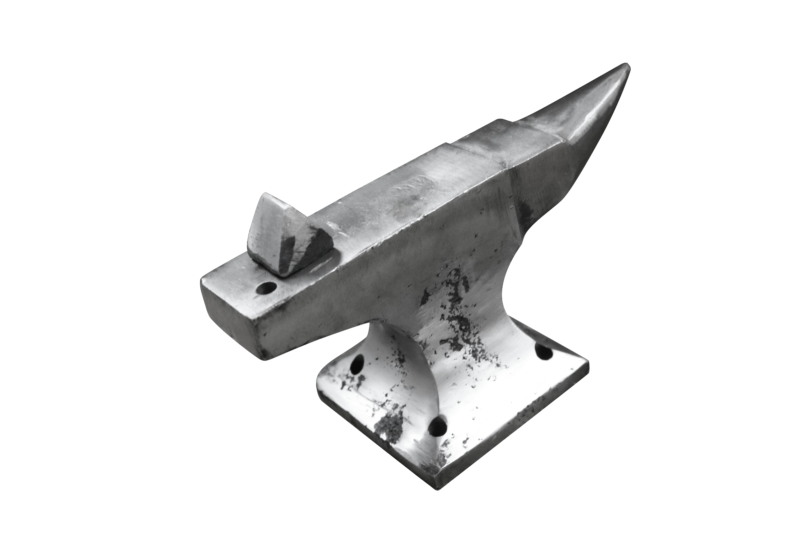

Mini anvil jimmy diresta tv#

My main chopping band saw was a gift from Craftsman when I did a TV show called Hammered. Tilt the bed, and it can cut metal at angles. These tools offer the ability to cleanly cut out thick sections of metal-say, a 4” block of brass or steel. The Bridgeport vertical mill precisely carves material out of a block of metal This system gives me a finer control over the mill motor’s speed.įigure 4-3. The new one is three-phase, and I have a variable-frequency drive (VFD) to control it. It came with a vise, indexing head, and a bunch of tooling.

It cost a lot of money to get it to my house in the Catskills from Jersey City. A friend of a friend of a friend was moving his shop and basically gave it away.

Mini anvil jimmy diresta serial#

Think of the Bridgeport as sort of a big drill press (seen in Figure 4-3) but with a powered X and Y bed, allowing you to precisely mill steel.Īccording to the serial number, my Bridgeport’s from 1965. The Beaumont belt sander was made as a tool for knife makers Now I’ll have one for my shop on the Lower East Side and one for my place in the Catskills.įigure 4-2. One of my fans was moving and couldn’t take it with him, and asked if I wanted to buy it. I bought it from the manufacturer in Ohio, a small company that makes each sander to order. One I’ve owned for about a year and a half (you can see it in Figure 4-2), and it’s starting to get a little beat up.

You can change the grits, and you can change the speed by jumping the pulleys, making this a versatile tool in my shop. It’s got a 2” × 72” belt and a 2 HP, 3-speed motor. I reply that the Beaumont is a belt sander made to sand metal-it’s really for knife making-but I use it for everything. Sometimes people ask why I’m using a belt sander to sand metal. I left out more commonplace tools you might see all the time, like hammers and screwdrivers, and instead focused on the big-ticket machines I use in my videos. The following are metalworking tools I use on a daily basis. In this chapter, you’ll learn how I built this machete In this chapter, I describe four metal projects I worked on recently: a steel box sign that employs a novel assembly method, a machete (seen in Figure 4-1) cut out of a saw blade, a table with aluminum legs milled on a lathe, and finally, a skull belt buckle carved out of wood and then cast in metal.īut first, I’ll share a selection of my favorite metalworking tools, ranging from my trusty Delta band saw to a selection of angle grinders, as well as my all-time favorite drill press.įigure 4-1. A lot of my videos came about simply because I wanted to try out a new technique. There’s still a lot I have left to learn, and I’m always trying out new ways of shaping and cutting it. I love working with metal: bending it, peening it, welding it. Workshop Mastery with Jimmy DiResta: A Guide to Working with Metal, Wood, Plastic, and Leather - Jimmy DiResta, John Baichtal (2016) Chapter 4.

0 kommentar(er)

0 kommentar(er)